I can do 4” all the way up to 16.5” prints wide, so that’s nice. I can and do produce more than one name brand printer with less effort per hour in my opinion, as long as my conversion was good( I really cheaped out on how I mounted the electronics and wish I hadn’t ). The printers I have about $2500 in the actual 3 p600’s and 1 P800, so all in all around $5,000 in the four, minus supplies. I know I have 4 active DTG printers and I have less than $2500 in the bases/conversions. It’s not hard, just annoying when an issue occurs and you get stuck, however that happens to anyone and anything new. I did use his base on 4 of mine, I made my own for the p800, based off of his base( hey it’s simple and it works).

You don’t have to use any of the kits for DTF, Andy has adruino code for an UNO listed as well if you want to wire it up yourself.

No worries and if it helps any at all, that’s good enough for me.

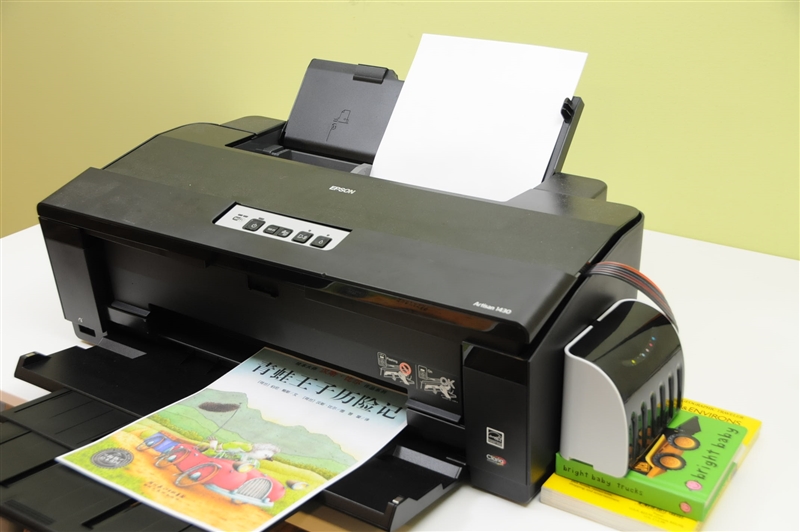

They’ll all work for it, but at the end of the day you’ll probably change your mind at some point into the future once you as well experience these issues and mistakes. My experience with this whole idea ( DTG/DTF) has proven otherwise to me, which has cost me quite a bit of unnecessary time and money. I thought I could make something “cheap” and work, as I always have done my entire life. Dtf requires so little ink it’s crazy, and a 6 channel printer would be totally acceptable for low/medium use.Īnyway, not knocking you or your decision in anyway, just stating what I went through. If it were me, I would have done that the other way around. One p600 can do that job of 4 1430’s, minus the hassles that came with them from my experience. They work and I made profit from them, but if you intend on using them for business purposes/sales that exceed more than 20 orders a day, you’ll end up moving forward from them rather quickly. For standard printers they are awesome though. For my level of printing they ? The 1430s) are too slow with only 2 white ink channels ( which are 90 nozzles each) and white ink is basically a far cry from acceptable unless it’s only spot white( like a small tree or “add-on” for light colored shirts). I started with two 1430’s for dtg, I tried everything, and ended up throwing them in the trash after a few months. I found it hard to remove the ciss and shake it without making a mess and mixing the ink adequately, on top of the ciss lines that come with most ciss kits are too small/restrictive for heavy flows like head cleanings/purges on the larger printers.

DTG does the same thing as DTF ink in terms of settling. The r3000 seems to be quite easy for the dtf, compared to the 1500w I have 3 1500w that I want to convert to dtg and to uv print For the quick reply, I ordered the ciss kit.

0 kommentar(er)

0 kommentar(er)